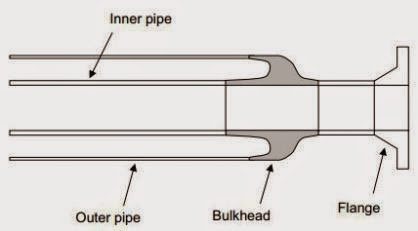

Pipe in pipe is another insulation method which an inner

pipe is covered by a larger outer pipe. The annuals between inner pipe an the

outer are filled with insulation materials such as micro-porous silica

(aerogel), polyurethane foam (PUF), wacker, mineral wool, etc.

|

Pipe in pipe section

|

Pipe in pipe is another insulation method which an inner

pipe is covered by a larger outer pipe. The annuals between inner pipe an the

outer are filled with insulation materials such as micro-porous silica

(aerogel), polyurethane foam (PUF), wacker, mineral wool, etc.

|

End Bulkhead

|

Water stops are installed to limit the pipeline length

damaged in the event that the annulus is flooded by pipeline failure or

puncture. Water stops are not design code requirement but they are recommended

for deepwater project whaere recovery of the flooded pipeline is challenging. EPDM

or ethylene propylene diene monomer rubber, viton, and sillicone rubber have

been used for the water stop material. The axial compression for the water stop

is provided by using an interlocking clamp arrangement whic will provide the

radial expansion of the ring against the pipe walls.

|

Water Stop Seal

|

Centralizers or spacers are polymeric rings clamped on the

inner pipe for reeled PIP to protect insulation’s abrasioan damage during

insertion of the ineer pipe into the outer pipe, to protect insulation’s

crushing due to bending load while reeling, and to protect insulation’s

crushing due to thermal buckling during operation.

Centralizer works as a heat sink due to its high thermal

conductivity. Therefore, reducing the number of centralizers by increasing the

centralizer spacing, or centralizer-less design can reduce both the material

and fabrication/installation costs. You can see the figure below to know the

shape of centralizer.

|

Centralizer

|

For the reeled PIP, the annulus gap needs to be sufficient

to put insulation material, centralizer, and clearance gap to account for the

weld beads, welding misalignment, pipe manufacturing tolerances, etc. The

annulus gap should be in the range of 30 to 40 mm and the net gap (between

insulation and outer pipe) should be 15 mm or higher. You can see the figure

below to know the what I’ve describe above.

|

| Reeled PIP with centralizer |

Reference :

Jaeyoung, Lee. Introduction to Offshore Pipelines and

Risers. 2007

Hello, an amazing Information dude. Thanks for sharing this nice information with us. Underwater pipeline repair

ReplyDelete