Subsea flowlines are used for the transportation of crude oil and gas from subsea wells, manifolds, off-shore process facilities, loading buoys, S2B (subsea to beach), as well as re-injection of water and gas into the reservoir. Achieving successful tie-in and connection of subsea flowlines is a vital part of a subsea field development.

Vertical Tie-in System

Vertical connections are installed directly onto the receiving hub in one operation during tie-in. Since the Vertical Connection System does not require a pull-in capability, it simplifis the tool functions, provides a time effiient tie-in operation and reduce the length of Rigid Spools.

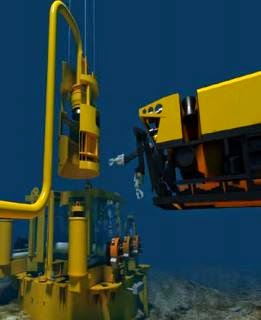

Stroking and connection is carried out by the the Connector itself, or by the ROV operated Connector Actuation Tool (CAT) System.

|

| Vertical Tie-in assisted by V-CAT |

Horizontal Tie-in may be used for both first-end and second-end tie-in of both flowlines, umbilicals and Jumper spools. The termination head is hauled in to the Tie-in point by use of a subsea winch. Horizontal Tie-in may be made up by Clamp Connectors operated from a Tie-in tool, by integrated hydraulic connectors operated through the ROV, or by non-hydraulic collect connectors with assistance from a Connector Actuation Tool (CAT) and ROV. Horizontal connections leave the flowline/ umbilical in a straight line, and is easy to protect if overtrawling from fishermen should occur.

|

| Horizontal Tie-in |

Considerations related to choice of connector can be seen in the table below

Connector

- Collect connector

Collet connectors consist of collet-style “figer” design which fimly locks around a mating hub. Collet connectors are used for both vertical and horizontal jumper spool connections and are available in both integral hydraulic and mechanical (with separate actuation tool) confiurations.Collect connector - Clamp connector

Clamp connectors consist of a two piece segmented clamp design and are particularly well suited for larger bore, lower pressure horizontal connection applications.Clamp connector

- Bolted flange

A bolted flange connection utilizes a metal gasket which is compressed to seal between two flanges. The bolts axis has the same orientation as the pipeline. When the bolts are tightened the metal gasket is deformed between the two flanges. The gasket allows the flanged connection to have some initial misalignment, but it is very vulnerable to rotational misalignment about z-axis due to the flanges respective bolt hole orientation.Bolted flange

Source :

Sletteb, Espen, 2012, Master's Thesis : Tie-in SPools - A Verification Study, University of Stavanger

Subsea Tie-in System brochure by FMC Technologies

No comments:

Post a Comment